R&D

R&D

More than 90 years technical inheritance and undertaken many technonoly project as a National High-tech Enterprise.

Successfully owned 30 independent innovation and technical patents.

Cooperated with Japan & Taiwan technical consultant to learn advanced technology.

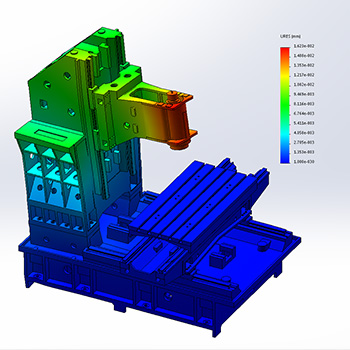

CAM & FEA software to ensure the

Manufacturing

Manufacturing

All castings will have twice timing treatment.

Top brand processing equipments from OKUMA, NICOLAS CORREA to ensure accuracy.

High functional equipments make advanced design possible to be applied in practice.

Assembly

Assembly

Full set of assembly SOP from Taiwan.

Experienced scraper workers inherited from conventional milling machine assembly.

Large production scale ensure highly standardization.

Inspection

Inspection

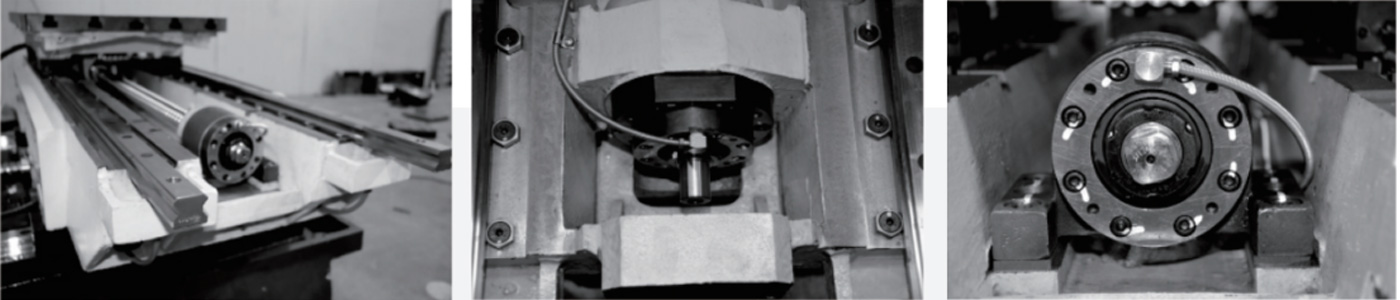

Accuracy inspection for each procedure

Spindle dynamic balance

Ball bar test

Laser interferometer

Trial running for 12hours

Leakage detection

Trial cutting samples for each machine and then test sample on CMM

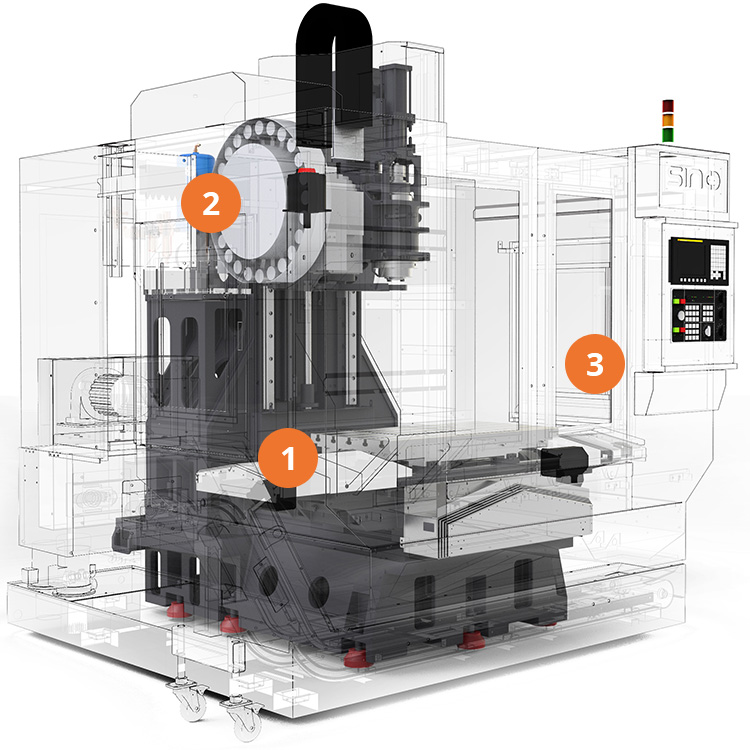

Unique Design ofSINO VMC

With advanced technology, which is with high rigidity and under repeated simulation and calculation by engineering mechanics and FEM. Machine body design is with high rigidity and 3 axes are all linear guideway. This machine is not only suitable for machining plates, discs, shells, precision parts, but for abrasive machining.

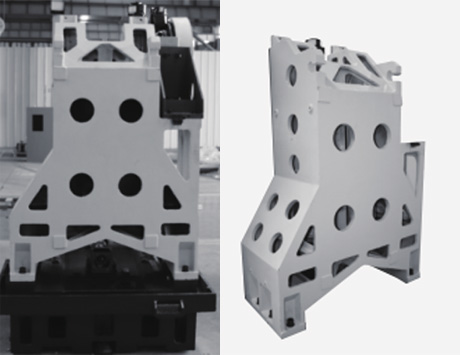

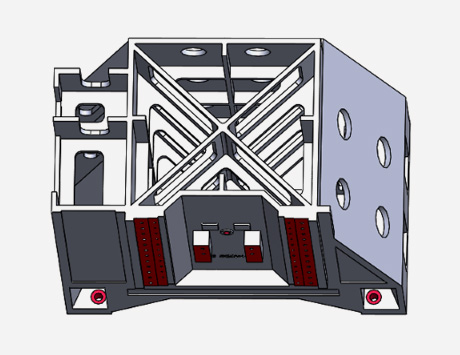

High Rigidity Structural Design

Large pagoda machine column and base ensure the highest stability during high speed movement.

The reinforcing ribs inside ensures strong enough rigidity.

Large span of Y axis guideways to keep all the X axis travel is supported.

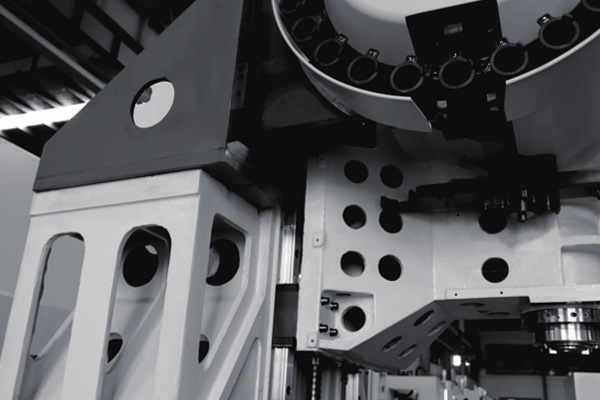

Shoulder Carrying Tool Magazine

Shoulder carrying tool magazine can ensure Z axis geometric accuracy and perfect stability, rigidity and the minimum deformation when column loaded with tool magazine weight.

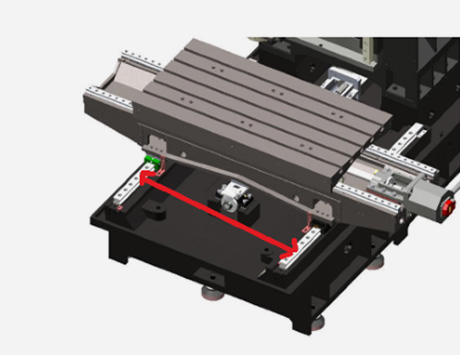

Preloaded, Directly Coupled and Double Anchored Ball Screw

In order to eliminate thermal growth and increase accuracy, all axes are driven by high precision double anchored ballscrews which are installed on intergrated ball screw housing.The ball screws are directly coupled to the servo motor. This eliminates the need for any transmission parts which may impact machine accuracy and efficiency.

Automotive Industry

As the biggest application area for cnc machines, SINO covers lots of customers for different parts.

Car Wheel

Special designed large travel of Y axis VMC for car wheel process

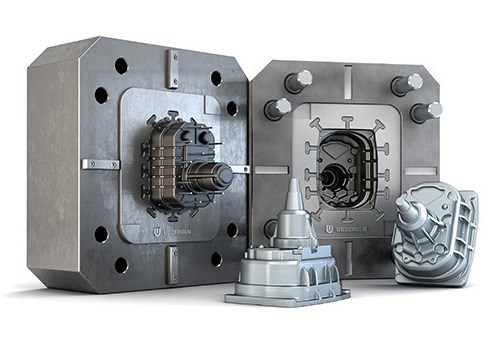

Precision Mould

High rigidity machine structure design and high spindle speed make SINO machines popular in mould area.

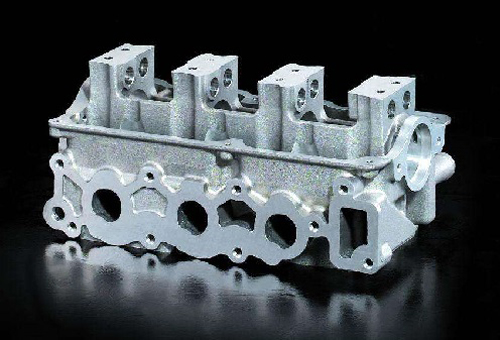

Engine Cylinder

More than 1100mm large travel of Z axis VMC for engine cylinder area.

Sewing Machine

Thousands of SINO machines in the workshop of top 1 brand sewing machine JACK.

Rotating Hook

Hundreds of machines in global biggest rotating hook manufacturer DSHOOK

Woodworking Tool

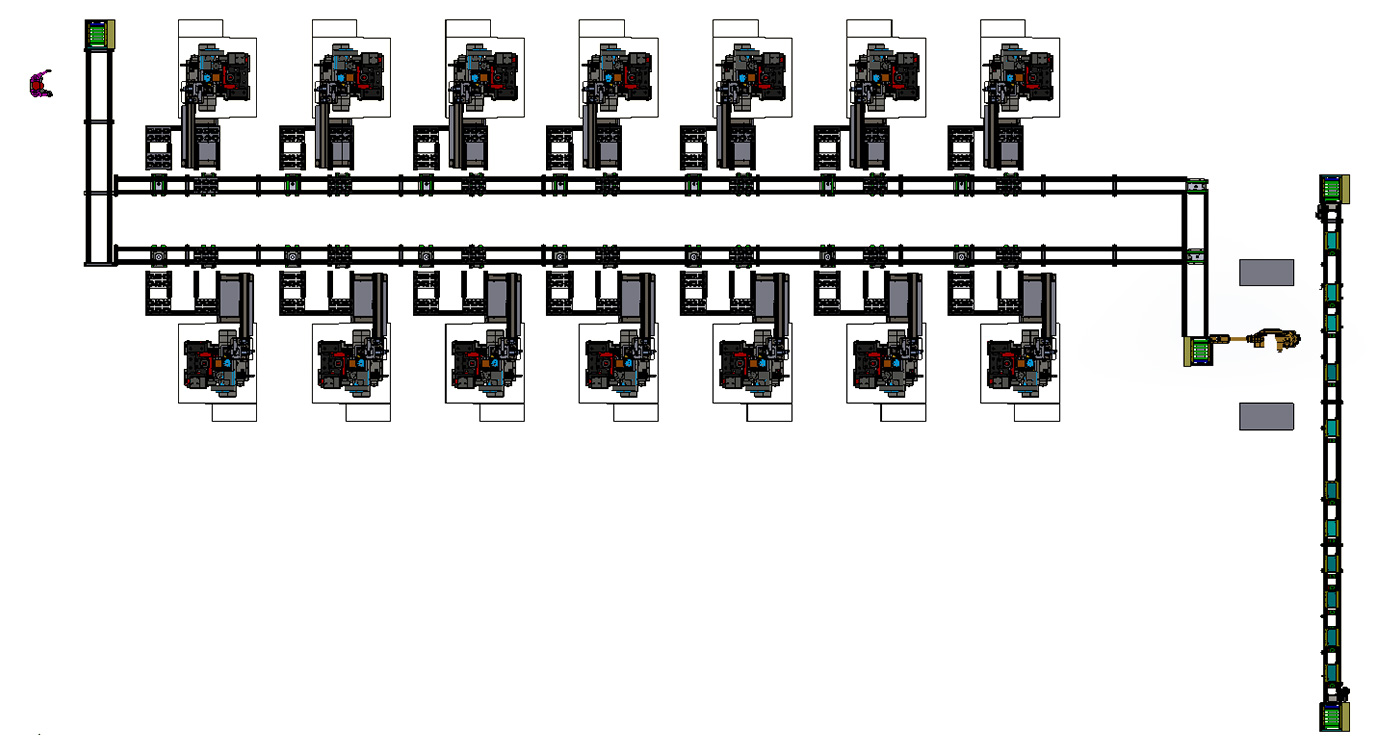

SINO automatic processing line supplied to top brand woodworking tool manufacturer SANHETIMBURLY.

Construction Equipments

China construction equipments got big development in past years, SINO machines were involved in many parts processing.

Presale service

Help to choose suitable model.

Supply whole solution include fixture, tools and production beat analysis based on drawings

Supply sample processing test and CMM testing data

Special purpose machine customization

Typical cases share from different industry area

After sale service

2 years mechanical warranty.

Service engineers can be flexibly arranged in customer workshop for technical support.

Spare parts supported in warehouse.

Free training

Free training for operator in customer workshop

Free training for maintenance people in agent’s company

Free training in SINO workshop

- Phone

- *Title

- *Content