Product Introduction

SVD650

Small Size but High Speed High Rigidity Vertical Machining Center

- 40

TAPER

- 3

AXIS

- 12000

RPM

- 20

TOOL CAPACITY

SVD650 Small Size High Rigidity Vertical Machining Center

SVD series is the newly designed series of machine SINO cooperated together with TAIWAN company.

The design concept, assembly know how and inspection method are all follow TAIWAN machine standard.

Product Detailed Parameters

Machine Model : SVD650

| Table | Value | Unit |

|---|---|---|

| working size | 850 x 400 | mm |

| Max. load capacity | 400 | kg |

| Travel | Value | Unit |

|---|---|---|

| X travel | 650 | mm |

| Y travel | 400 | mm |

| Z travel | 500 | mm |

| Spindle | Value | Unit |

|---|---|---|

| Spindle nose taper | BT40 | |

| Spindle speed (pulley) | 12000 opt.15000 | rpm |

| Feed | Value | Unit |

|---|---|---|

| Rapid traverse rate | 48/48/32 | m/min |

| ATC | Value | Unit |

|---|---|---|

| Number of tools | 20 | T |

Product Details Map

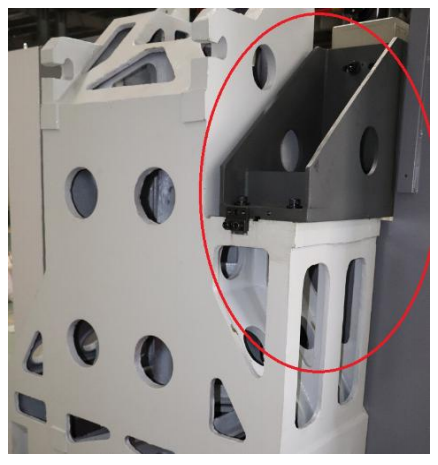

Machine structure :

The contact ratio between spindle case and column increased to ensure spindle rigidity.

Wide machine body span and optimum supporting design can meet with fast feed of X and Y axis.

Big size of “pyramid” column and closed inner cavity to ensure low center but high rigidity support of Z axis.

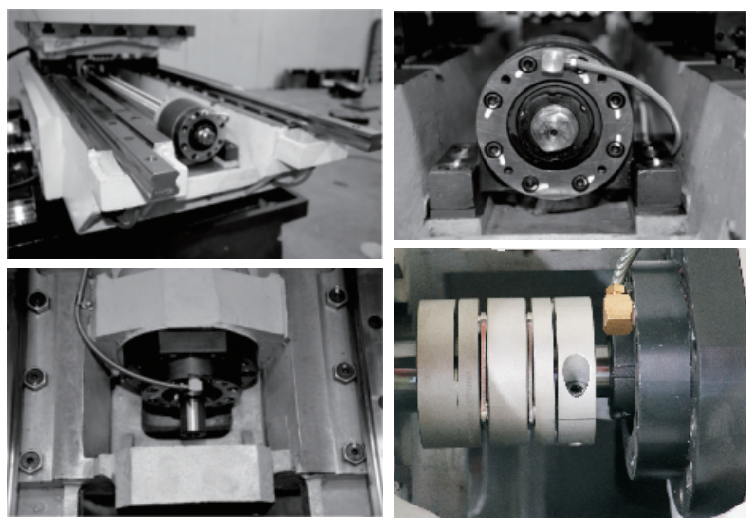

Preloaded and double anchored ball screw :

Servo motor directly coupled ball screw which is fixed on the intergrated nut seat which can keep stable accuracy.

All the ball screws, linear guideway, bearings are well lubricated in time and ration.

In order to eliminate thermal growth and increase accuracy, all axes are driven by high precision double anchored ballscrews.

4 rank high precision angular contacted bearing installed aside the ball screw and make pre-tension.

Shoulder carrying tool magazine :

Shoulder carrying tool magazine can ensure Z axis geometric accuracy and perfect stability, rigidity and the minimum deformation when column loaded with tool magazine weight.

Lengthened and heavier load linear guideway sliders

Lengthened and heavier load linear guideway sliders than normal designed offer better dynamic loading performance.

Dynamic rating load improved 22%, static rating load improved 33%.

-

Spindle (Direct Driven) :

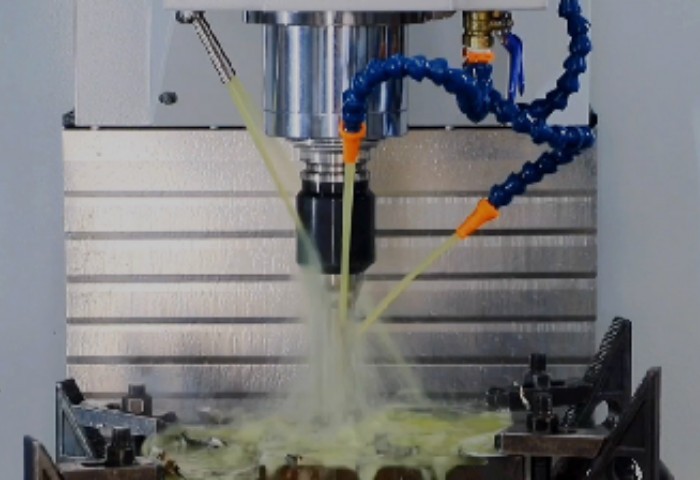

Spindle large flow to ensure the sufficient cooling of workpiece.

-

Flushing:

Inner chip flushing with angle shield design at the bottom.

Reply your inquiry in 24 working hours.(our normal working time:6:00~22:00)

Experienced staffs answer all your questions in time.

Customized design is available.

Exclusive and unique solution can be provided to our customer by our well-trained and professional engineers and staff.

Special discount and protection of sales are provided to our distributor.

Professional factory: We are manufacturer, specializing in producing all kinds of CNC MACHINING CENTER.

As an honest seller, we always use superior raw material, advanced processing/testing machines, skilled technicians to ensure our products to be finished in high quality and stable feature.

- Phone

- *Title

- *Content

- Phone

- *Title

- *Content